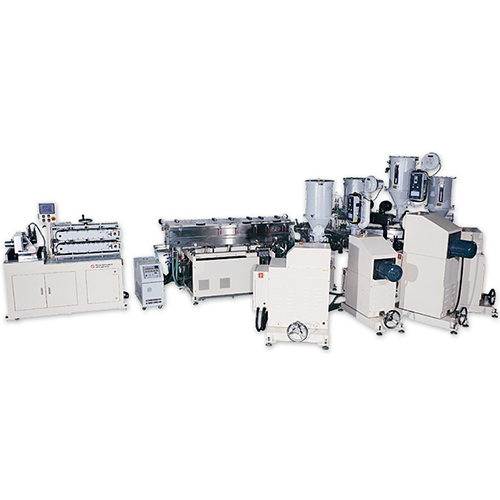

Multi-Layer PE Tube Co-Extrusion Line EDC-08-05

Categories : Cutting Machines

Plastic material has its own characters. In co-extrusion system. We use and combine several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE)Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc.

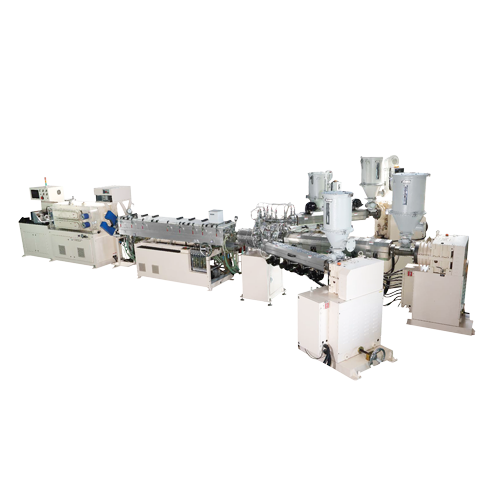

High Speed Multi-layer PE Tube Extruder and Cutting Machine EDC-16-05

Categories : Cutting Machines

-High speed & high output -High precision thickness control on each layer of tube -Simplified control -Quick tooling change by one operator -Closed loop cooling water circulation system -Caterpillar haul-off -Automatic outer diameter control unit (optional) -Low power consumption and high production efficiency

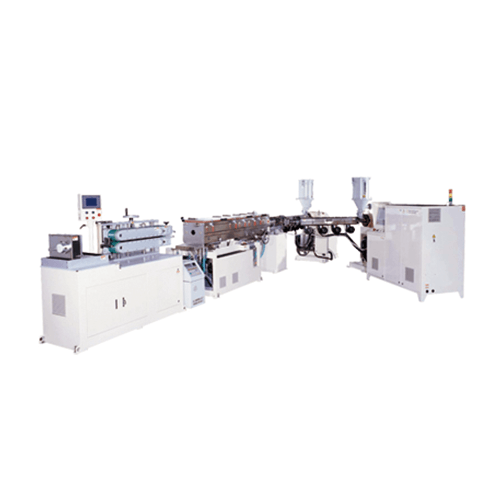

Two-Layer PE Tube Extruder & Cutting Machine EDC-08-02

Categories : Cutting Machines

-Two-layer extrusion tube can reduce material cost. (using: Pearl + PE/PE + Pigment) -The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility. -The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes. -Using the same material on two-layer same material on two-layer co-extrusion can increase the water-resistance and anti-penetration of the materials for about 20~30%. (using: PE + Pigment. inner: recycled material.)

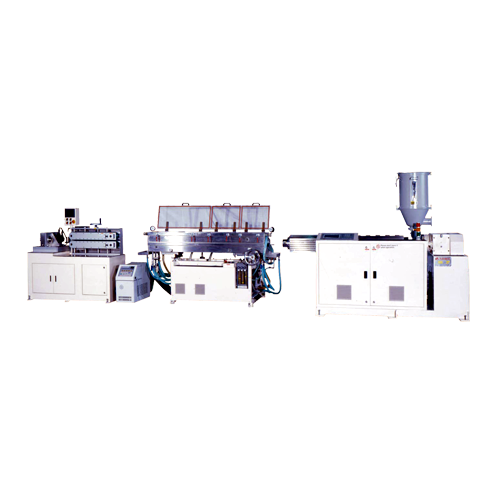

Mono-Layer PE Tube Extruder & Cutting Machine EDC-08-01

Categories : Cutting Machines

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials. For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface treatment, together with size control by figuration and length restraint by encoder have produced valuable and high-quality tubes.

PPV Proportional Pinch Valve

Categories : Separators

Product Serial: PPV Pinch valve works in a way to open or to close a fluid path in a flexible tube by squeezing or pinching the tube. With a proportional pinch valve, the shaft that pinches the tube is driven by a stepper motor, thus that the extent of pinching can be adjusted, which indirectly controls the fluid flow rate inside the tube. The advantage of using a pinch valve is that it has no contact with the fluid, making it an ideal option for biotechnology processing, food industry, dosing system, blood process/analytical, CIP and SIP process, and biopharmaceutical equipment. Our PPV series pinch valve is driven by the PM series driver that accept either analogue ( 0-10V or 4-20mA) or digital RS485 modbus signal. What is a Proportional Pinch Valve? A Proportional Pinch Valve is a type of pinch valve that combines the characteristic and features of a pinch valve and a linear stepper motor. It is a great way to control fluid flow or fluid pressure in applications that emphasize sterile, clean, non-contact, avoid cross-contamination environment, such as Biotechnology Chemical Processing Dispensing, Filling, & Mixing Process Equipment Bioreactors Medical Devices Pharmaceuticals Life Sciences Food Processing In this article, we will start by introducing what type of proportional pinch valve KaoLu could offer, followed by the working principle, and when should you use a proportional pinch valve, and then conclude with what you should consider before making a decision on which valve to purchase. What type of Proportional Pinch Valve does KaoLu offer? KaoLu offers mainly two types of proportional pinch valve – miniature and high torque version. Miniature version: please click on photo to product brochure ,or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html Three versions are now available: PPV-04, for tube outer diameter (O.D.) 3.5 – 4.5 mm (~0.125” to 0.188”) PPV-06, for tube O.D. 5.5 – 7 mm (~ 0.25” ) PPV-08, for tube O.D. 7 – 9 m (0.375”) The tube O.D. is flexible because we are using flexible plastic tube, and as long as the tube can fit into the insertion slot, it will be functional. The higher torque version is suitable for soft and more rigid tubing, up to durometer of 75 shore A. Please click on photo for product brochures, or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html It is available to up 5 different sizes PPV-930-64 – tube O.D. 6 – 7 mm (~ 0.25”) PPV-930-95 – tube O.D. 9 – 10 mm (~0.375”) PPV-930-127 – tube O.D. 12 – 13.4 mm (~0.5”) PPV-930-191 – tube O.D. 18.6 – 19.6 mm(~0.75”) PPV-930-254 – tube O.D. 24.8 – 25.8 mm (~ 1”) All our proportional pinch valve can be controlled by either analogue (0-10V or 4-20mA) or digital signal. There is also an option for encoder. For the correct selection of product, please contact our product consultant. We also provides a video demo on how proportional pinch valve function, please visit and subscribe for our latest videos. https://www.youtube.com/watch?v=5z31SR9wqgk What is the Working Principle of a Proportional Pinch Valve? A proportional pinch valve combines the features and advantage of a pinch valve and a linear stepper motor. Let’s firstly introduce you the concept of these two items. Pinch Valve A pinch valve works in a way by pinching or squeezing a flexible plastic tube through a shaft that can be controlled by solenoid electromagnetic principle, by pneumatic pressure, or by a linear stepper motor. Pinch valve is especially useful in applications that does not allow valve to be in contact with the fluid inside the tube, such as chemical reagents, food, corrosive fluid…etc. A traditional pinch valve only provides full open or full closure function, and the disadvantage is that there is a flow rate drop when the tube is inserted into the pinch valve, and there is no way to control fluid flow rate. Linear Stepper Motor A linear stepper motor is a type of actuator that used the characteristic of a stepper motor to achieve linear motion. The degree in which one can control a step distance and torque is greatly dependent on the control system and the stepper motor quality and characteristics. A stepper motor is commonly used when one requires high resolution, high repeatability, and high torque. Pinch Valve + Linear Stepper Motor = Proportional Pinch Valve The combination of both provides an excellent solution for application that requires an automation on process line that requires sanitary environment and applications that require cleanliness and sterility, as well as highly accurate incremental flow or pressure regulation. This eliminating the need for multiple-valve, high-maintenance assemblies, and this single valve offers a compact, efficient solution. When should I use a Proportional Pinch Valve? KaoLu is expert in pressure and flow regulation. Please refer to the graph below: Pressure Regulation: The left had side is the control of inline pressure with a traditional on/off pinch valve. The right hand side shows the pressure control with a proportional pinch valve. In a process line that does not allow fluid to be contaminated, one could consider a proportional pinch valve to adjust the inline pressure by controlled the opening of the tube via a proportional pinch valve. With a fine step control, the pressure could be adjusted in a high resolution manner. Flow Regulation: The graph shows that the inline fluid flow rate could be regulated by a proportional pinch valve. The curve could be shift leftward with either a higher resolution stepper motor control or by adjusting zero offset of the pinch valve. With a proportional pinch valve, one can easily control (non-contacting method) the inline fluid pressure and flow rate, this offers a great advantage to many industries. What should you consider when purchasing a Proportional Pinch Valve? 1. Tube: outer diameter, material, shore A, inner tube pressure 2. Performance: resolution, repeatability, can achieve desired accurate flow or pressure control 3. Control: analogue or digital control We called it TPC. It is important to understand the characteristics of the tube you are using and the operating pressure. Sometimes, a suitable tube may not work if you have a high inner tube pressure which the pinch valve could not squeeze or pinch at all. Secondly, the performance of the proportional pinch valve should be taken into account when choosing which brand of proportional pinch valve is suitable for you. With KaoLu’s proportional pinch valve, we are able to achieve up to 40000 steps per revolution and the velocity in which the pinch shaft moves to squeeze and the torque of the motor could be calibrated easily by our customers to suit different requirements. The third important factor is control method. With our digital control method, it is possible to operate the valve half a mile away from the valve itself. We also provide RS485 holding register where the user could adjust zero offset and other parameters to fit customized solution. Please visit our product website for further information. https://www.genndih.com/pinch-valve/proportional-pinch-valve.html and remember to visit our youtube channel and subscribe for latest video updates: https://www.youtube.com/channel/UCjQ9bjuSOT_csnVA9if4_EQ/videos

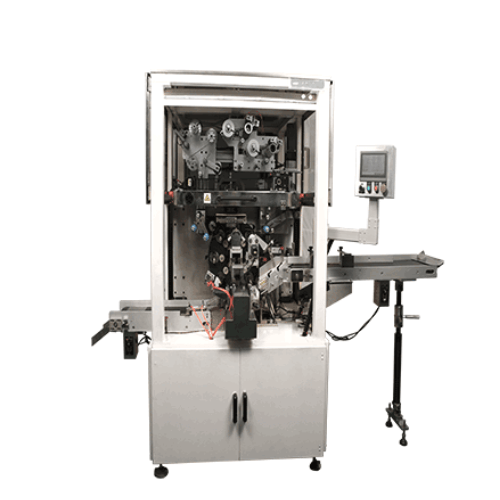

Plastic Tube Hot Stamping Machine HSM-50-01

Categories : Hot Stamping Machines

Touch panel control. Hot Stamping with servo motor control. Two colors of hot stamping are available. Automatic I-Mark registration. Automatic unloading conveyors for Good and NG products.